EMSNOW Executive Interview: Marco Gonzalez Hagelsieb, COO Sanmina Integrated Manufacturing Services

Sanmina is a Fortune 500 integrated manufacturing solutions provider that designs and manufactures high technology electronic, optical and electromechanical products for the world’s most innovative original equipment manufacturers (OEMs). When you text or talk on a cell phone, use an ATM or point- of-sale terminal, drive a car, stream a video, use cloud services or fly in a plane, chances are you are interacting with products developed or manufactured by Sanmina.

Founded in 1980 in San Jose, CA, the company operates in approximately 20 countries, producing hundreds of millions products annually across markets that include the communications, cloud, industrial, medical, defense and automotive sectors.

At its facility in Guadalajara, Mexico, Sanmina partners with advanced technology leaders to produce complex optical products. With experience in optical technology and microelectronics, the facility provides test engineering, process engineering and new product introduction (NPI) services for component, module and system-level applications, including fusion splicing and fiber tray manufacturing. EMSNOW caught up with Sanmina Chief Operating Officer Marco Gonzalez Hagelsieb to learn about recent trends in that region.

EMSNOW: Please give us some background on your lengthy career at Sanmina.

Marco Gonzalez Hagelsieb, Sanmina Integrated Manufacturing Services COO

Sanmina has provided me with excellent career growth over the past two decades. Most recently, I took on the role of COO for the Integrated Manufacturing Services division of Sanmina across the South Asia Pacific and greater China region. Prior to this role, I was COO for the US, Canada and Mexico for several years. I also spent nearly a decade managing our factories in Mexico, so I’m deeply connected to the region.

I studied Electronics Engineering extensively in college, receiving a BS, Masters and an MBA in the field.

EMSNOW: Please tell us more about Sanmina’s Guadalajara facility and the customers you serve there?

Sanmina’s Guadalajara campus was established in 1987, initially serving the PC industry. Over the years, the business expanded to support telecom, industrial, automotive and medical customers as these markets grew rapidly and required a global footprint of services and solutions that Sanmina provides.

Our culture embodies a ‘can-do’ attitude and our people are our biggest asset. We continue to invest in our people through educational programs like Sanmina University that provides training, certification and a path for continued career growth at Sanmina.

EMSNOW: How has the pandemic changed the way you do business in Guadalajara? How has the pandemic impacted the business operations at the facility? How are your employees doing?

As a global manufacturer, many existing programs and procedures at Sanmina greatly aided our ability to respond and adapt when the pandemic first arrived. Our business continuity management system was developed at a global level, so that processes, procedures and templates were already set up for distribution to ensure consistent practices. Whatever the crisis might be, we have an established set of actions based on risk assessment and recovery. These guidelines and procedures are activated in times of crisis, whether for a natural disaster or a pandemic.

The pandemic changed the way we do business and we’re very proud of the way we quickly and successfully adapted to the transition. First, we had to adjust to working from home for non-production floor -related jobs. Second, we had to adjust to interfacing with our customers via web conferencing since customer visits were not allowed. After initial restrictions to the number of people physically allowed to work at our facilities were lifted, we were able to ramp production back up to full capacity.

Our employees across all of our operations have embraced safety protocols and procedures that enabled Sanmina to operate safely and with very few disruptions. This has been a team effort between our human resources, quality and operations teams, as well as close coordination with local government entities.

EMSNOW: What are the main challenges that the EMS industry in Mexico now faces?

Many OEMs are looking to implement a regional approach to their operations in order to reduce risk, so that they aren’t dependent on a single area or location for manufacturing services, when a future unexpected event arises. As our customers consider a regional strategy, Sanmina is well positioned with operations across the Americas, Asia and Europe. Mexico offers state-of-the-art manufacturing with a highly experienced team to support our customers as they look to move business locally to best serve their customers.

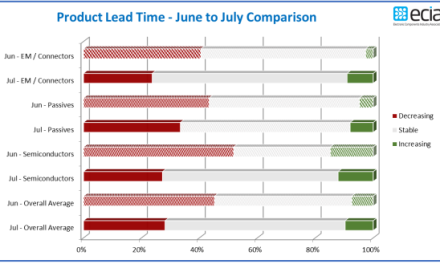

The main challenge, not only for Mexico but also globally, is the supply shortage that’s limiting the production of electronic products.

EMSNOW: OEMs are concerned about the supply chain disruptions of the past two years. How is Sanmina responding to the component shortages and other disruptions?

We have an experienced global supply chain team that is one of the best in the industry. We continue to work closely with our customers and suppliers to secure supply of these critical components. We believe the supply chain constraints will continue to be challenging over the rest of the calendar year 2022.

EMSNOW: What long term impact do you think all these disruptions will have on OEM’s outsourcing requirements?

The good news is that the need for hardware is NOT going away. The rise of the Internet of Things has driven high demand for smarter and more connected products. A great deal of complex electronic hardware is required to support software and other digital platforms. This includes datacenter products, computers, servers, telecommunication equipment, fiber optics links, 5G radios, smart devices, electric vehicles, industrial controls and equipment. The demand for these products is an excellent growth opportunity for Sanmina.

EMSNOW: What end market sectors do you see being most affected by these trends?

Every product that requires semiconductors is affected by supply chain constraints, whether it is in the communications, computing, automotive, industrial, medical or defense and aerospace industries.

EMSNOW: What opportunities do you see for the expansion of electronics manufacturing in Mexico?

We are poised to capitalize on opportunities that will materialize as a result of regionalization efforts being undertaken by some OEMs to bring certain aspects of manufacturing closer to their home operations. Electronics products are only getting smarter and more complex and require deep expertise that only EMS providers like Sanmina can provide.

Going to Mexico has been a critical part of the supply chain for a long time and Sanmina has been operating there since 1987. Mexico has proven that it can deliver leading technology, but it will be imperative that the region remains competitive, from the sourcing of components to the availability of a skilled workforce.

EMSNOW: What else would you like to say to EMSNOW readers about trends in the industry in 2022?

Our customers are looking for a company like Sanmina that is prioritizing its employees, the environment and the sustainability of their products and operations. This includes exploring alternative, more eco-friendly raw materials, developing products with longer life spans and ensuring that customers have comprehensive refurbishing or recycling programs in place for products that are at the end of their life.

They are also looking to design more products that are ideally suited for automation and robotics to increase productivity and reduce costs during production. Sanmina provides key capabilities to support its customers across all of these areas.

There is great demand for highly complex products and Sanmina is poised for growth when the pandemic and supply chain constraints ease. We have a strong financial position and remain confident in our ability to weather any economic environment. We are excited about the future and know that we will come out of this a stronger company.