What is Traceability for Electronics Manufacturers?

By Jonathan Simard, Product Manager, Analytics & Traceability, Cogiscan

What exactly is traceability for an electronics manufacturer? Since it’s not something that’s regulated industry-wide, requirements vary widely as they are usually customer-driven or specific to certain safety-critical markets such as products used in the automotive, aerospace, or medical sectors.

At Cogiscan we’ve been installing traceability solutions in electronics manufacturing plants worldwide for over 20 years now, and each project is unique. Driven by what’s accessible from the factory floor, the level of granularity the customer needs, as well as the type of reporting requirements, each traceability solution ends up differing slightly.

Put succinctly, a traceability solution will equip manufacturers with detailed reporting of the complete production process. Typically, it answers the following questions:

Example: The Journey of an Instrument Cluster

To answer the above questions with the types of traceability data available during production,let’s walk through the manufacturing process of an instrument cluster. Starting from the very beginning through each assembly step as raw materials are transformed into a final unit to be put into the dashboard of a brand-new electric vehicle.

Due to the modularity of our traceability offering, our clients can track as much or as little as they would like. For the sake of this example to better showcase the depth and breadth of information available, we’ll illustrate a comprehensive and robust traceability solution.

1 – Pre-production

Identification of all PCBA’s and Raw Materials

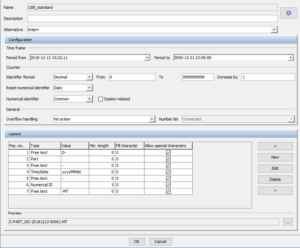

All PCBA’s must be identified with a serial number to uniquely identify and track each unit throughout the entire manufacturing process. This can be done automatically by a laser marker machine or can be hand placed with a barcode sticker. The serial number is the most important factor in a traceability solution as it is captured at each assembly process step to tie all gathered data directly to that unique PCBA.

The format of the serial number is flexible and can be customized by customers. Users can create custom rules, such as assigning a range of numbers to specific end customers or they can dictate the orientation of the visual representation of the barcode.

2 – SMT: Assembling the PCBAs

At Cogiscan, it’s our goal to make collecting traceability data as quick, easy, and painless as possible by utilizing automation and machine communication. Each manufacturer has their own unique processes and machine sets – and we leverage the industry’s largest collection of Co-NECT machine interfaces, including hardware and software flexible enough to adapt to almost any electronics assembly environment, so we can customize the best way to capture data to feed your traceability system.

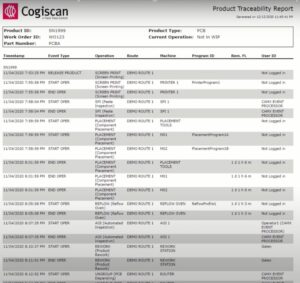

2.1 – At the start of the SMT line is the screen printer.

As these machines typically don’t have a camera to capture the PCBA’s serial number, we usually add our Product Flow Controller in front of this machine to get that data. Tracking and recording material details such as the stencil information and type of solder paste used, as well as process data such as squeegee speed, snap off speed, print direction, and underside cleaning.

To inspect the performance of the screen printer, a lot of manufacturers today will have a Solder Paste Inspection (SPI) machine. Most importantly here, through the utilization of our Co-NECT machine interface, we can automatically collect and track the SPI’s results with defect descriptions and images including the component part number to the reference designator.

The meat of the SMT process happens at the pick and place operation and the richness of traceability data available reflects this. Detailed information on all placed components includes supplier information, lot number, reference designator & remaining floor life (when an MSD is involved). Additionally, setup information such as all used feeders can be traced.

For manufacturers with a pre-reflow inspection solution, such as TTC Fix, we can automatically collect and track the same type of results as with an SPI – defect descriptions and images including the material part number to the reference designator.

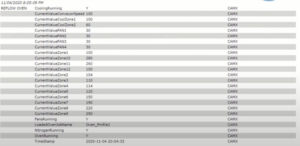

To solder all SMT components to the circuit board, the unit heads into the reflow oven. Arguably one of the most important processes of SMT, the oven holds a lot of critical process data key to the functionality of the finished unit. We can collect and track all relevant data such as the program name and process details such as conveyor speed, profile specifications, and actual measured temperatures within the different zones.

At the end of the SMT line, the PCBA will usually go through an Automated Optical Inspection (AOI) machine to inspect and validate the quality of the SMT process thus far. Similar to what’s collected and tracked for an SPI machine, here we will collect inspection results with defect details to the reference designator. A hyperlinked image of the defect is also available within our traceability reporting.

3 – Post SMT: Manual Operations, Testing & Final Assembly

At these stations, the PCBA’s serial number will be manually scanned to track and record the materials used or replaced, work steps performed, as well as the operator performing the repair work.

Coupled with iTAC’s traceability module, we can also gather details on the cycle time (the amount of time spent on the repair), the flagged defect code versus the actual defect code since a change can be made during the repair process or upon further inspection.

Like the type of information that is collected and tracked at the repair process, at manual assembly, we will gather the materials used, work performed, the work instruction documentation used, as well as the operator who performed the work.

To complete this instrument cluster unit, the PCBA will now go through the electro-mechanical assembly process to add any wiring and housing required to encase the board in its final form. With our genealogy functionality, we have multi-level BoM tracking, which links any subassembly’s serial number directly to the final assembly and vice versa. With “trace up” and “trace down” functionality, users can quickly identify and tie all units together.

Before preparing this unit for shipment, it needs to go through the testing process to ensure functionality. With either ICT or functional testing, we trace all test results with complete measurement data compared to the test recipe’s specification limits. Additionally, operator information and applicable defect codes will be included.

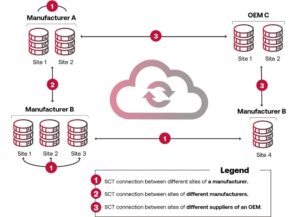

To prepare for shipment to the end-user each instrument cluster will bepacked into a larger box containing multiple units. All details related to packing include the station where packed, the date it was packed, the types of boxes and materials used for packing, as well as which final units by serial number are in each box. If needed, manufacturers are also able to track and record the pallet information and total weight. For manufacturers with multiple plants, we also offer supply-chain traceability– sharing the complete traceability record with the next intra-plant to perform the next level of assembly.

Conclusion

And there you have it – the detailed manufacturing traceability journey of an instrument cluster for an electric vehicle. Tracking the transformation of materials, we highlighted what details are available to track and record at each manufacturing step. Since your situation may call for something different, please don’t hesitate to contact us to find out the best approach for your traceability installation.