Keeping Up with a Constantly Evolving Manufacturing Environment

Sean Murray, VP of Customer Success at Bright Machines

There are a few overt obstacles manufacturers have been grappling with, such as ongoing supply chain disruption that has impacted nearly all industries for years now—and though bottlenecks have felt less extreme in recent months, the Russian war against Ukraine and unpredictable COVID-19 outbreaks across various regions will likely slow down any progress made to date. In addition, the ongoing labor crisis has impacted the manufacturing sector. While manufacturers added 55,000 jobs per the April 2022 job report, there’s still a record number of unfilled positions, with Deloitte estimating that 2.1 million manufacturing jobs will be unfilled through 2030.

For decades, other issues have also been lurking with no easy or obvious solution. Implementing more sustainable practices, for example, is not only the right thing to do for the planet, but many customers, vendors, and government bodies are likely to start demanding it from their manufacturing partners. Upending traditional manufacturing practices – many of which aren’t eco-conscious and contribute significantly to CO2 emissions – requires time, resources, and willingness to change.

Yet, despite these hurdles, there’s finally some momentum within the manufacturing industry. For example, it was reported that capacity use for the industrial sector (i.e., how fully and effectively organizations are utilizing their resources) rose by 0.3 to 77.6% earlier this year, though still nearly two percentage points below its 50-year average. However, the manufacturing sector increased by 0.9 to 78.0% in February, 2.5 percentage points higher than it was before the pandemic.

Progress is being made, but there’s still plenty of room for improvement. Manufacturers looking for ways to increase operational resiliency further, not just to overcome the labor crisis but to foster new, fruitful workforce opportunities and create more sustainable, efficient processes for the betterment of the planet, need to consider building and creating where they sell.

How manufacturers can better keep pace with today’s fast-changing environment

Manufacturers who have a market to support reshoring and nearshoring operations (i.e., moving production back to the U.S. or closer to the U.S.) would be positioned to more efficiently address issues in real time and prepare for, even prevent, any challenges that lie ahead. What’s more, closer-to-home production checks all the boxes for many of today’s manufacturing goals, including enabling faster time to market, reducing reliance on the strained global supply chain, and creating new careers that have clear growth paths.

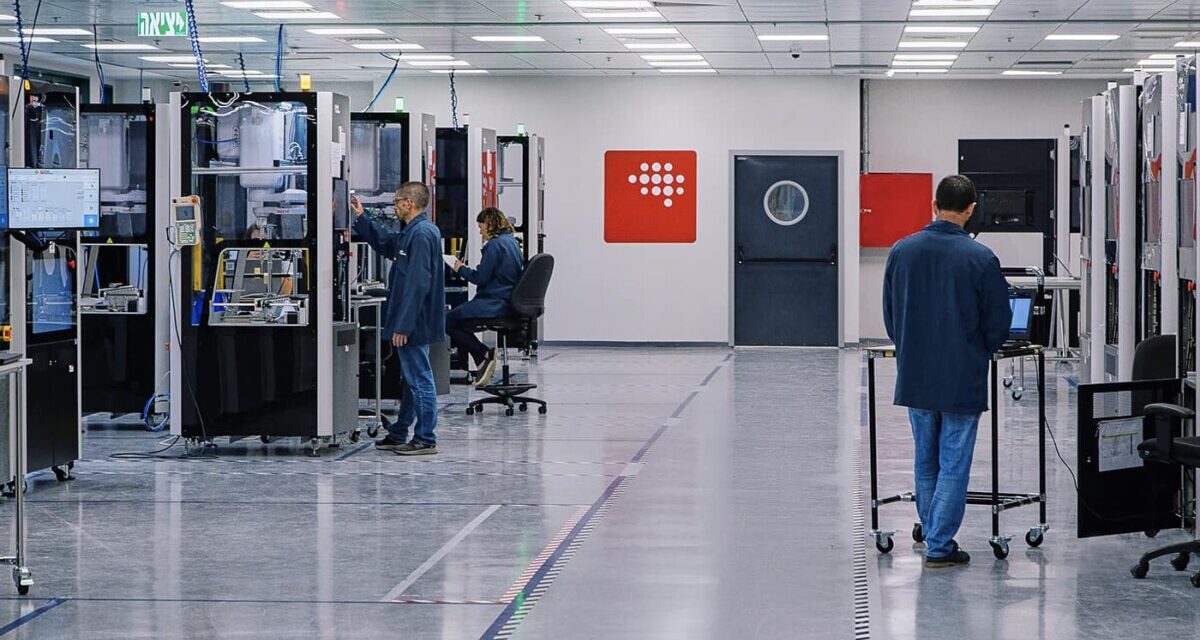

However, moving operations home means changing the way things have always been done. Specifically, manufacturers will have to lean on intelligent automation and smart factory solutions that enable fast deployment and flexible production. The good news is that leadership is already aware of the benefits of today’s technology applications—according to a PwC survey, 60% of executives say digital transformation is their most critical growth driver this year.

All backed and made possible by modern solutions, here are a few key areas of change that manufacturers should consider if they want to keep up in today’s fast-changing environment:

- Reshore to reduce your supply chain risk: As noted, manufacturers who move production closer to the customer reduce reliance and minimize the risk associated with the global supply chain, such as geopolitical conflicts, trade tariffs, and factory closures due to COVID-19 outbreaks. By reshoring or nearshoring, they’ll also experience various cost-savings elements, such as reduced transportation and warehousing fees, which were recently up 16% compared to a year ago. Some manufacturers might also consider mirroring their overseas operations at home, meaning they can create well-managed redundancy that can help offset any surprises or issues that impact operations in one location by picking up production in another.

- Adopt flexible solutions to adjust to local demand: Manufacturers who adopt intelligent platforms that are inherently flexible and provide real-time insights can more easily reorganize production and position themselves to deliver on local customer orders promptly. For example, if a new product receives a poor response from the market, or when there’s an ask to produce a broader range of products, flexible automation solutions can quickly be programmed to accommodate new instructions – all on the same line, all with the same equipment.

- Establish upskill/reskill programs to retain and attract talent: The combination of reshoring or nearshoring with intelligent solutions built into factories creates new, more fulfilling career opportunities for the workforce, many of whom are no longer willing or interested in the mundane, tedious tasks associated with traditional manufacturing. New positions in local factories will require an understanding of modern technology, calling on robotics, artificial intelligence, and machine learning experts to get operations up and running quickly and help navigate the nuances of evolving demands. Manufacturers need to embrace the opportunity to upskill and reskill current employees by establishing specific programs or initiatives to do so. This will help them not only retain top talent but attract new talent entering the workforce looking for exciting careers that have an enticing trajectory.

- Lead the way with more sustainable production: Large factories located halfway around the world inevitably contribute to land and air pollution due to shipping and transportation requirements to get the final product in the hands of the end customer. In fact, supply chain emissions are 11.4 times higher on average than operational emissions. Manufacturers who build smaller, energy-efficient factories closer to the customer lower their carbon footprint and reduce emissions. Not only do they stand to make operational improvements for the betterment of the planet, but they can set an example for other manufacturers looking for a blueprint on how to do the same.

It can feel like the obstacles that manufacturers have to overcome today are growing in complexity and number. Still, there have also been great strides towards creating a healthier, more robust sector. Luckily, we’re now in a place where there are various strategies and approaches that manufacturers can embrace today to not only become more resilient but to truly thrive.