When implementing factory analytics, shop-floor connectivity isn’t as simple as it seems

By Michael Ho, Director of Business Development, Cogiscan

Analytics Starts With Good Data

Michael Ho

I met with a wide range of customers within electronics manufacturing – both mid-sized and large EMS suppliers and OEMs – and while each of them faces unique challenges implementing a factory digitalization strategy, the biggest takeaway for me is that shop-floor connectivity is still a major hurdle for all players.

And while connectivity is simply a means to an end – with the end goal as some form of factory analytics (more on that later) – connectivity is the baseline foundation for ANY factory digitalization initiative. While our industry is 5+ years into building smarter factories, many of the key players still struggle with developing connectivity in-house.

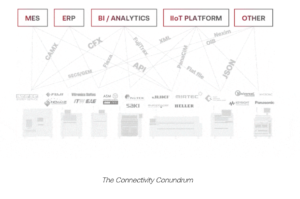

Machine Connectivity: too many brands, models, vintages…

Most electronics manufacturers have a diverse equipment install base consisting of a wide range of vendors, models, and vintages. Typically, each of those vendors (and even vintages within vendors) have different requirements to tap into the data source. It’s no easy feat to access and requires extensive collaboration with the equipment manufacturers.

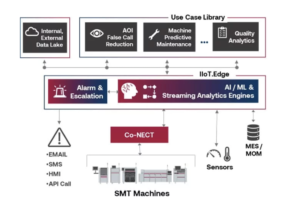

Lucky for me, I work for the top connectivity providers in electronics manufacturing. Within our Co-NECT platform, we have the largest library of machine and software interfaces (partial list available here) developed over 20+ years. Our neutral position, and strong equipment partnership strategy, also eliminates the issue of connecting competing machine and software vendors.

Rather than wasting internal resources to try and understand all the nuances and requirements of the different machine types and vintages, it’s a better choice to rely on out-of-the-box adapters to immediately tap into production data.

In fact, ARC Advisory Group recommends “that manufacturers, machine builders, system integrators, and suppliers to machine builders use a third-party solution to speed up implementation, which will lower the total cost and speed up the time-line of providing connectivity, avoiding in-house solutions in which the time and expense would be substantially greater.” (full report here) With the Co-NECT platform, factories can check that connectivity box quickly and then dive into the more tangible (and fun) efforts of factory digitalization, like Factory Analytics.

Reaching the next level of Factory Digitalization

Figure 1: IIoT.Edge diagram