Less Science Fiction, More Data Analytics: Unlocking the Potential of AI

By Brian Ballweg, Sr. Principal Engineer, Automated Solutions, Plexus

Originally published on Plexus Blog

Brian Ballweg

In retrospect, the basic processes in manufacturing have not changed much. For example, PCB manufacturing has been running at a high degree of automation for many years. What’s new are the technologies to process and use the multitude of data to make manufacturing more productive, in the truest sense of the word. Optimization of operating time, predictive maintenance and increased efficiency of the entire system are the key objectives here.

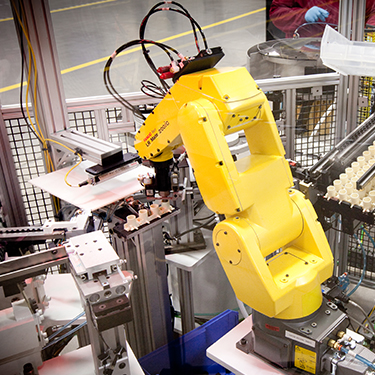

Today, AI is closely associated with robotic automation solutions in manufacturing. Robotics can be described as “intelligent”: a machine captures and processes information, makes decisions based on this database and repeats this process each time it is performed. Sensors and cameras linked to robotic arms allow the machine to place and mount the components of an assembly in the correct location. Even when loading and unloading machine tools, or when transferring products and components from one conveyor belt to another, manufacturers have been using robotic technology for some time. The use of robotics is not new. In the past, however, production processes were limited to highly automated motion sequences with few variations. In many cases, they also did not represent an economically viable option for cost-sensitive manufacturing.

Technological progress is breaking down these barriers.

These examples certainly do not show the full extent of what AI can do in manufacturing. However, they provide good guiding principles in order to pragmatically tap into the potential of AI. The key to short-term implementation is to limit the scope of integration to specific technologies. AI is too often equated with an omniscient machine capable of knowing and ultimately controlling everything about the world around it. In practice, it is more useful for companies to focus on integrating and analyzing large datasets within their manufacturing facilities. It is important to capture more data to better program and control automation solutions. The more connected the data, the more context is created that allows AI applications to recognize patterns, learn and apply patterns to different processes.

“Real” AI will most likely not find its way into manufacturing sites in the production itself, but rather in the products to be manufactured. Progress may seem slow. However, in ten years the production landscape will change significantly. Manufacturers should take the time to gradually adapt and extend their technologies to meet the needs of AI. This cannot and must not be done by companies alone. OEMs are well-advised to work with partners on current and future opportunities to optimize manufacturing processes. In which applications within a high-mix, low-volume production environment does the use of AI make sense? How does robotic manufacturing affect the design-for-manufacturing process? What new technologies must be integrated into both products and systems to ensure comprehensive data analytics, even as data volumes increase? They can also look beyond their own teams and benefit from industry-specific expertise in machine learning, data analytics and AI.

AI implementation will change business models unmistakably – for both manufacturers and customers. Predictive and prescriptive maintenance and high quality control will enable sophisticated products and take the usability of devices and systems to a new level. The time-to-market will be shorter and products will be appearing at a higher frequency in the marketplace, meaning that the window of opportunity for innovation is now. Despite the hype, AI remains for manufacturers what it is – an opportunity and a challenge.