Improve ECAD project accuracy with a good dialogue between schematic and layout software solutions

Software for schematic drawing helps you define the logical connections between the various components that you find on the circuit board. In addition to looking at what is connected to what, it’s crucial to define the physical relationship between the various elements as well. This is where software for layout comes into play. By showing how each component is physically positioned on the printed circuit board, layout is what is used to design it.

The following is some background on the Siemens Solution, offered by Cadlog

By Ivano Tognetti, Technical Manager, Cadlog

Companies like FutureNet, Omation (with its solution called Schema), Orcad and ViewDraw by ViewLogic were only active in the schematic segment.

From Verticalization to Integration

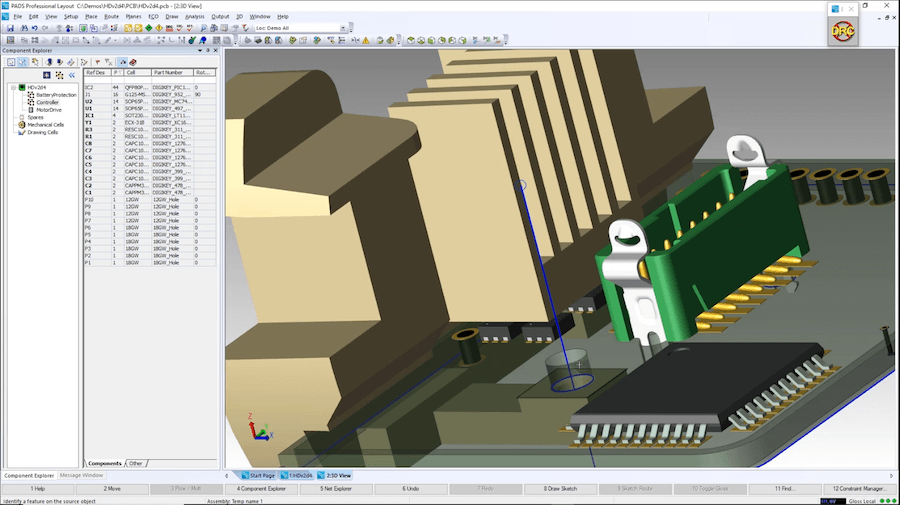

One of the most famous software solutions was PADS by PADS Software Inc. PADS offered PADS Logic (a base schematic-entry tool) and PADS Layout.

A series of acquisitions happened during the years: ViewLogic and PADS became Innoveda, then Mentor and very recently Siemens.

During the following years a more advanced schematic solution called PADS Designer and based on ViewDraw’s engine entered the market (an entry-level schematic capture plus basic constraint entry, design navigation, logical reuse, and cross probing with layout).

During the years, Siemens gradually expanded the features of their solutions. Strictly speaking, the well-known PADS Standard, PADS Standard Plus and finally PADS Professional solutions are based on the new Integrated Flow concept and commercialized as a package together with PADS Designer.

The Integrated Flow

The key element of success lies in the quality of the dialogue between schematic and layout. Siemens is not the only company offering such packaged solutions but Siemens is the only company that can benefit from a tight and tested integration between them inside a proprietary environment. This integration allows PADS Designer to provide a seamless and efficient flow of information towards PADS Professional (Layout).

A good integration has three main benefits:

- It eliminates design errors

- It digitizes the information exchange

- It guarantees the adherence to the design intentions

Imagine this typical situation. A designer and a layouter are working on a project. During a period of absence by the layouter, the designer edits the project. He forgets to tell his colleague and there are no alerts. The layouter comes back to the office and resumes his work on a project that is no longer the latest version. This creates a misalignment.

This is exactly where Siemens’ solution comes into play. The Integrated Flow solves any miscommunication by creating a synchronous exchange based on a common database. In our previous example, upon coming back to work, the layouter would receive an alert the moment he opens his tool, be able to see what has been edited and take the appropriate actions. The result is a virtuous project scenario in which all different environments play according to the same rules.

Ivano Tognetti, has been working in the EDA sector since 1986, with a wide technical experience in the field, both from an application and systemistic point of view, on the whole electronic production chain.

He mainly deals with:

- Technical direction and customer support management on CAD/CAM/CIM applications.

- Management of pre-sales technical support, with specific analysis of design and production problems also on a large scale.

- Organization of post-sales activities and training on operating systems and applications.

- Specific consultancy in the electronics market on issues of design, creation and production of printed circuit boards, assembly, product/process/material traceability and quality.

For more details, feel free to contact us: info@cadlog.com www.cadlog.com