How to tackle 15 electronics manufacturing challenges: Technical Guide from Critical Manufacturing

Speed and accuracy in New Product Introduction (NPI), adapting to new components and suppliers, and managing complex manufacturing processes, are just some of the challenges in electronics manufacturing.

A product may involve thousands of components and several processes, requiring thorough traceability from raw materials to finished goods.

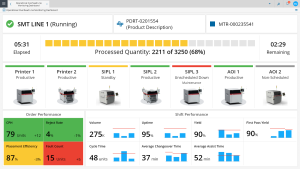

To address these challenges, a modern Manufacturing Execution System (MES) designed for electronics manufacturing is crucial.

Developed by Hugo Leite, Critical Manufacturing product manager for Electronics/SMT, the technical guide “Advanced MES Critical Capabilities for Electronics Manufacturing” explores 15 manufacturing scenarios, identifies key challenges, and discusses the advanced capabilities an effective MES must support to meet these demands.

The challenges are in many categories

- Data: master data management and analytics

- Supply Chain: planning, materials, and WIP management

- Process compliance: recipe management, BOM validation and traceability

- Assets: equipment management and monitoring

- Quality: defect handling, sampling, golden board runs

- Speed to market: NPI and automation

- People: operations guidance and people engagement