EMSNOW Mexico: Covid-19 Update

According to government officials, Mexico is shut down until May 30 for all non-essential activities. The auto industry is considered a non-essential business. Even factories that produce emergency medical equipment have to prove 10% of their orders are for Mexico before they are allowed to open and manufacture.

We spoke to Elliot Shev, General Manager of Sumitronics USA Inc., with manufacturing facilities in Tijuana, Mexico. He describes a situation that reminded me of that Lucille Ball episode in the chocolate factory. Until one or more of Sumitronics’ customers is deemed to be an essential business, the employees at his factory are ordered to stay at home. .

“Our warehouses are full of finished goods, much of it for the auto industry. My customers are not able to accept these finished goods as they are closed as well. And on the other end, I have shipments of parts coming in on boats from Asia that I must accept,” he lamented. “Car sales have slowed. It’s nearing the end of a model year. There is a rush to reopen the auto industry, but who’s buying the cars?”

The situation in Mexico is especially complicated because the industry is global. The Mexico-U.S. border is still open for essential products, and workers can go back and forth as normal as long as the activity is related to an essential business. “The government is very strict with that designation, however,” warned Shev. “If it is non-essential, it isn’t going anywhere. Factories are being inspected regularly and managers must prove that the line is for an essential business. If a company makes toys for Fischer-Price and ventilators for a medical OEM, only those employees and machines that are making the medical products are allowed to operate.”

Factories are also being inspected regularly to ensure that employees are protected. “We have had safety measures in place for six or seven weeks at our facilities, so when we do open again, we will be ready,” continued Shev. “Our employees don’t work close together, but we have formalized social distancing, including in the time out areas and cafeteria. Everyone wears face masks; employees get their temperatures checked when they arrive; hand washing and extra disinfecting of the work areas has been implemented. The problem is, there isn’t as much of that going on in Tijuana, even though the bars and restaurants are closed. I worry about the employees when they are not at work.”

The expectation is that Mexico will open up for business again at the end of May, with some companies trying to get exemptions to restart in mid-May. “This is all TBD, however, depending on how many people get the disease,” noted Shev. “And when the automobile sector does open up, it will depend on if the whole supply chain is functioning. Unless Mexico, the United States and Canada all come together, we won’t be able to open back up.”

Source: Mexico News Daily

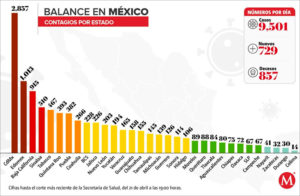

Some Areas Are Harder Hit than Others

Tijuana is in the state of Baja California, which has the third highest number of cases of any state in Mexico. In Jalisco, the governor has taken Covid-19 more seriously and measures to lock things down began earlier. There have been 226 cases and 15 deaths in Jalisco, so far; lock down measures have been extended to May 17th. Jalisco is closing its border with other states, and checking temperatures of people coming and going to other parts of Mexico.

Clearly the EMS industry has responded quickly to these rapidly changing business conditions. Flex has ordered all employees that can work remotely to do so and has instituted rigorous employee safety measures to those that work in facilities that are producing essential products. Cafeterias have been redesigned to ensure social distancing; visitors have been banned for all but the most critical reasons; employees get their temperatures checked every day and those that are sick are isolated. Since in Mexico most jobs include transportation, the buses taking employees to and from work have to be sanitized every day as well.

We spoke with Bernardo Dibildox, Program Manager at Flex in Guadalajara. “We have been working from home since March 15th. Flex closed facilities that make non-essential products, but globally has dramatically ramped up production of medical products,” he reported. “We have just launched 12 lines around the world to make face masks, mostly for internal use, but after our employees are covered, we plan to donate to hospitals and government workers that need them.”

Flex is heavily involved in supplying equipment to the medical community. They have customers that make body scanners, monitors, test kits, hospital beds and much more. “Just to get a sense of the scale of the ramp up, in the past year, total global output for all manufacturers was 24,000 ventilators. We are on course to build 24,000 ourselves in June 2020 alone,” he marvelled.

When asked about supply chain issues coming from the pandemic, Dibildox said that at the end of February, there was a big spike of shortages. “It was very freaky in February with thousands of parts having problems. Within a month we were able to reduce those shortages by finding alternative suppliers and so forth.”

Dibildox expects that the next couple of quarters will be very bad. But the overall outlook for Mexico is strong due to several trends that he says were in motion before the pandemic started. “Like other economic crises, it may take a long time to get back the demand. It could take as long as 6-12 quarters; but some things will change permanently. For one, I see a major acceleration of regionalization in manufacturing. And not just contract manufacturers moving from one geography to another, but bringing manufacturing in-house.

“Second, I see an acceleration of allowing people to work remotely. It is working well and companies will gain confidence in their employees doing that. Third, I am seeing many positive signs of solidarity among people who are being very creative in adapting and responding to this crisis. People are helping each other, and doing what they have to do to survive. It’s very inspiring to see people rise to these challenges,” he concluded.

The next few weeks will be critical. Experts believe Mexico may be heading for a surge of cases as testing catches up. We hope hospitals and doctors are able to get the disease under control soon.

For more updates about the Covid-19 crisis, including an interview with Elliot Shev, please register for The Eric Miscoll Show on May 5.