EMSNow Executive Interview: Bill Cardoso, Creative Electron

EMSNow caught up with Bill Cardoso of Creative Electron recently for his insights into the state of the world. Described by his Creative Electron colleagues thusly: ‘Our benevolent overlord is an overeducated Brazilian who became an electronics technician at 13, continued in life to get a BS, MS, and PhD in Electrical Engineering, and topped off with an MBA. While taking way too many classes, Bill ran a top engineering design department at Fermilab, the leading high energy and nuclear physics research lab in the USA.” I actually just ran into him setting up the Creative Electron booth at SMTAi in Chicago, so he’s also clearly a hands-on guy. Here’s what we were discussing:

EMSNOW: I know you present at many industry shows and gatherings, so we are interested to hear your insights from the audiences you engage with. How many shows have you attended so far this year?

Dr. Bill Cardoso

Dr. Bill Cardoso: Between expos, trade shows, and conferences, we’re at 22 this year in 22 different cities around the world. A big part, and often the best part, of my job is to keep my fingers on the pulse of the market and to visit with our customers in their different locations. The internet and online meetings are great, but nothing replaces a face to face chat to get a real understanding for what’s going on.

EMSNOW: How would you characterize the general business environment for electronics manufacturing today?

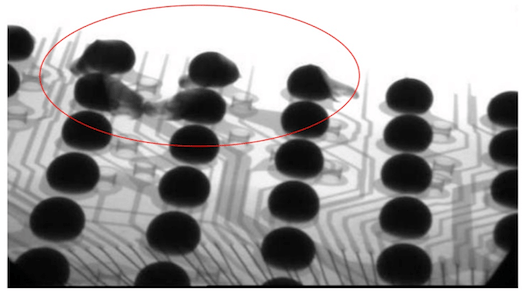

Dr. Bill Cardoso: We have an interesting barometer to check the health of the electronic manufacturing market. As the leader in x-ray inspection for counterfeit components, most of our customers in this area are independent distributors. Independent distributors (IDs) are the first line of defense for component shortages, since they stock components that may have long lead times in the authorized distribution channels. We hear from IDs first when the market is picking up. Unfortunately, an uptick in the electronic manufacturing activity also means an uptick in counterfeit components, which lasts until the component supply chain capacity catches up with the increased demand. The combination of component shortages and proliferation of counterfeits are really hurting the industry right now!

EMSNOW: What development do you find people are the most excited about?

Dr. Bill Cardoso: Technology building blocks that will help us achieve Industry 4.0 or the smart factory excite people in this industry and rightly so. The application of technologies like AI or digital twins will accelerate the industry along the journey to smarter more efficient manufacturing. It’s becoming well known in the industry that we are the leaders in powering x-ray machines with artificial intelligence. Most people have heard about AI and are somewhat familiar with the technology, but they don’t fully understand how to apply it to solve their application problems. For the past two decades, the industry has focused on automation – how to move things faster and more reliably. I believe the next revolution in automation will focus on automating the decision-making process, and that’s where our work in AI has become paramount to the next generation of SMT machines.

EMSNOW: What are the major concerns that people express to you?

Dr. Bill Cardoso: Alongside the issue of component shortages and counterfeiting, the recent changes in the global political landscape is a large topic of conversation. Tariffs, globalization, protectionism, are words commonly used. It is clear we’re in transitional times, and the market is trying to understand the impact of the new policies.

EMSNOW: What are their major challenges?

Dr. Bill Cardoso: One the main challenges, especially in the US, has been recruitment. The low unemployment rates we are experiencing have challenged companies’ ability to scale production to meet customer demands. But that issue is not limited to the US. I was in Poland last week, where EMS companies are also having a tough time recruiting operators to keep up with their growth. To increase efficiency of the line, EMS companies have invested in modern assembly and inspection equipment. This investment has increased the level of experience needed to run a line, both from the ability to program machines and the ability to interpret their output. As a result, our industry we have reduced the number of people needed to run an SMT, but in turn we have increased the experience and skill needed for those people. When we have a sharp upward turn in the economy, finding people with these specific skill is challenging, leaving in-house and on-the-job training as the last recourse, and at times, the only option available.

The recent uptick in the economy combined with the desire of certain manufacturers to cease manufacturing of certain components is causing severe shortages, a widespread problem in the industry today. The direct result of these shortages is the increase in the number of counterfeit components entering the supply chain. We’ve been developing x-ray machines to detect counterfeit components for the past 10 years, so we’ve seen a substantial increase in interest for this equipment, especially when combined with parts counting and AI.

EMSNOW: What has surprised you?

Dr. Bill Cardoso: Our industry has been globalized and homogenized to a point where problems that used to be local are now global. We live in a world where EMS companies can design a supply chain by looking at a world map. As a result, these decisions are placing significant pressures on local governments trying to keep up with the demands of these companies, from taxes incentives to education curricula. I was surprised by how many local governments around the world are dealing with the same challenges, including what to teach kids for the industry of today or tomorrow. The question is, are these companies going to stick around long enough to benefit from these investments?

EMSNOW: Are there any other insights gleaned from your travels that you would like to share?

Dr. Bill Cardoso: Globalization and nationalism have been the topic of educated discussions in the aisles of trade shows and conferences worldwide. We can’t argue that the results of a globalized production and supply chains are positive to the companies running them. Some argue that these benefits haven’t been properly distributed to the people supporting them. However, the “flat world” they created benefits smaller companies like Creative Electron and many others. The globalized economy allows us to navigate to different geographies and to quickly understand their problems. It allows us to design a machine in San Marcos, California, that can solve a problem for a company in Krakow, Poland. Globalization quickly unites problems and problem solvers. But most importantly, it creates a landscape that connects us and enables a machine made in San Marcos to be deployed in Krakow. In an ideal scenario, it creates a more efficient economy that allows the best solutions to bubble up and dominate. Not every scenario is ideal, and sometime the world is not as “flat” as we would like, but the principal of the best solution rising to the top to solve a problem is compelling!