Consortium-supported Blockchain Applications: Responsible Sourcing

By Quentin Samelson, Sr. Managing Consultant, Global Business Services at IBM

Several earlier blogs[1] discussed the idea that some blockchain applications would be best developed by a group of companies – a consortium – rather than by one “founder.” Two applications were covered in those earlier blogs – anti-counterfeiting and materials content declarations (MCD). Both of those deal with knowing critical information about what goes into an electronic product. Two more have been proposed and in fact are well along in the development of both their respective consortia and their applications. Both of them deal with problems encountered by electronics companies as they source goods and services.

Electronics companies already have complex supply chains – especially because of the large number of components that go into creating an electronic product. But companies have seen a series of developments over the last decade or so that have created even more complexity. One of those – RoHS and similar legislation – is the cause of the MCD use case. Another of those developments is legislation like Sarbanes-Oxley in the USA, which has created a need for companies to maintain better control over their supplier on-boarding processes. (The negative publicity that some companies have experienced from disclosures about partners’ behavior or policies has encouraged them in the same direction.) Unfortunately, those improved controls have tended to make their supplier selection and approval processes more expensive and slower.

The other new source of complexity was the recognition that some of the most critical metals used to create electronic products are sometimes mined in ways that are widely viewed as unethical or exploitative. Human rights issues in this case are primarily associated with minerals that are sourced from central Africa (esp. Rwanda and the Democratic Republic of Congo). These issues first came to light with so-called “conflict minerals” (Tin, Tantalum, Tungsten and Gold), where the proceeds from the minerals sometimes went to fund local militias. More recently, Cobalt has received negative publicity as being responsible for the use of child labor in the same region. These minerals are used extensively in electronics manufacturing. Cobalt, for instance, is used in batteries – which many electronic products (e.g. mobile devices and electric vehicles) rely on.[2]

As quoted in Industrious Magazine, [3] “Everybody wants to make sure the products they’re using don’t contribute to worker violations or promote child labor. There’s an incentive for companies to prove that their products are ethically sourced,” said Max Nelson, a Global Business Development Executive for Industrial Products with IBM Global Markets.

Besides electronics companies’ desire to source in a responsible, ethical manner, governmental regulations in some countries require that products sold in those countries use responsibly sourced (non-conflict, non-child-labor) minerals. Add to this the possibility of bad publicity for companies that rely on their good reputations, and this becomes a critical problem for the electronics industry.

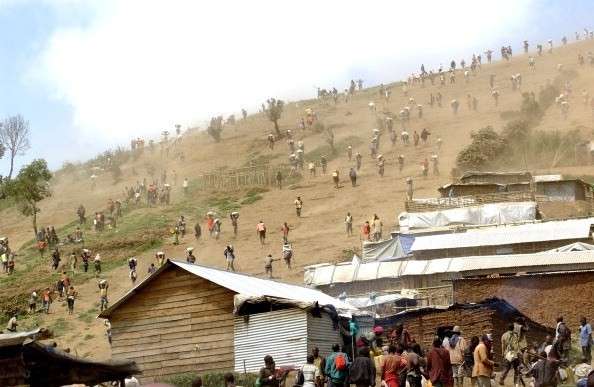

To be sure, most electronics companies have built processes to ensure that they only source components from companies that practice responsible sourcing of raw materials. But companies have discovered that it is extremely difficult to verify the actual source of these raw materials. Creating processes that can be fully audited is hardly straightforward, since much or all of the critical activity occurs thousands of miles away. Minerals may originate in large-scale mines, or may be produced by “artisanal miners” – often subsistence farmers who mine with not much more than a pickaxe when their farms do not require attention. Even minerals from larger mines may go through a middleman before they reach a smelter, but artisanal miners’ minerals – which literally may start out as a sack of rocks – often pass through multiple stages before they finally reach a smelter.

Using Blockchain technology does not require ripping out existing methods (although over time it may well reduce reliance on the most manual and time-consuming elements of those methods). Additionally, the solution can be constructed to support the responsible sourcing standards developed by the Organization for Economic Cooperation and Development (OECD) and promoted by the Electronics Industry Citizenship Coalition.[4]

Blockchain’s excellent provenance capabilities offer an obvious way to create a verifiable, audit-able tracking process. Further, because blockchain records are immutable, once a transaction has been accepted by the blockchain it is permanent, providing additional security. A number of companies – not only from the electronics industry – have already recognized this and have come together to create a “Responsible Sourcing” solution, starting out with cobalt but with the potential to be extended to other minerals. Early members of the blockchain network include Ford Motor Company, IBM, Hauyou Cobalt, LG Chem, and others.[5]

The initiative will benefit more than the large OEMs: “Traditionally, the miners and smelters have had to comply with third-party audits and laborious manual processes to prove their compliance. As we move to a blockchain-enabled process, they won’t have to expend so much time and effort on these manual processes,” says Sai Yadati, Blockchain Partner at IBM and the Program Manager for the Responsible Sourcing effort.

You can find additional information about the Responsible Sourcing initiative at https://www.ibm.com/blogs/blockchain/2019/01/blockchain-for-the-mining-industry-ethical-cobalt-production/

[1] [1] https://www.ibm.com/blogs/insights-on-business/electronics/blockchain-solutions-sometimes-it-takes-a-village-i-e-a-consortium/ and https://www.ibm.com/blogs/insights-on-business/electronics/consortium-supported-blockchain-applications-anti-counterfeiting/. The third article in the series is at https://www.ibm.com/blogs/insights-on-business/electronics/consortium-supported-blockchain-applications-materials-content-declarations/

[2] A short but informative video on this subject can be viewed at https://ibm.co/2VDFryb

[3] The online “Industrious” Magazine explains the issues with cobalt mining in its fifth issue: https://www.ibm.com/industries/industrious. An interesting column on the topic of “artisanal” mining is at https://www.reuters.com/article/artisanal-mining-ahome/column-for-cobalt-buyers-is-artisanal-mining-the-problem-or-the-solution-andy-home-idUSL8N1QC64O.

[4] The electronics industry as a whole became involved in socially responsible business practices early on, and set up the EICC over a decade ago. See, for instance, http://www.csrwire.com/blog/posts/349-conflict-minerals-supply-chain-responsibility-spotlight-on-the-eicc

[5] Now including VW: see http://www.mining.com/web/volkswagen-group-joins-responsible-sourcing-network/