Confronting Challenges in the Heavy Equipment Industry, Sustainably

Heavy equipment manufacturers have faced unprecedented challenges in the last three years and have been forced to reevaluate their processes and systems like never before. The disruption is by no means over. Fallout from the pandemic continues to impact operations and affect the bottom line while social shifts are creating new dynamics that impact the way companies work.

To help you stay competitive, we’ve audited the main challenges facing the heavy equipment industry and outlined how best to tackle them, keeping increasingly important Environmental and Social Governance (ESG) considerations top-of-mind.

Supply chain disruption and its implications for businesses and consumers alike have been a consistent feature of news headlines around the world in recent years. Two global events – the pandemic and war in Ukraine – have brought into focus the delicate nature of long, intricate supply chains. The heavy equipment industry, which relies on the seamless movement of a great variety of large and small components, has felt the ripple effect of supply chain disruption hard in the last three years. Short-term factors and rapid changes have shown themselves to have long-term effects. Access routes to certain components heavy equipment businesses have used and relied on for years can be blocked off in an instant – but alternatives can take years to find.

In these circumstances, it is critical to be dialed into the constraints and fluctuations of a highly dynamic market. Increasingly, manufacturers have found that while they used to worry about the larger scale components in their supply chain, some of the smaller and most inexpensive parts have recently become the most constrained.

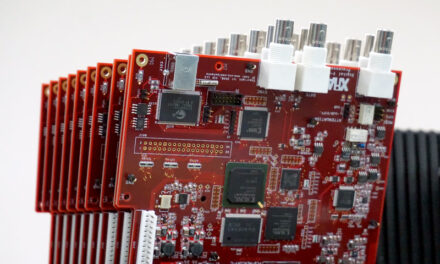

Working with a partner like Plexus to help you analyze your total mix of components, identify risks and identify the parts for which alternatives can be most readily sourced will enable you to address gaps more quickly and, in turn, give you the confidence to confront such challenges more robustly in the future. Moreover, reconfiguring your supply chain in this ad-hoc fashion could be the catalyst for realizing a need to restructure it altogether, and a partner like Plexus would be perfectly placed to help you expand your existing supply base from one supplier to five different ones, for example.

Product concept to manufacturing

Another major challenge manufacturers have had to contend with is rising component costs. When access to parts is restricted, prices rise. What’s more, the cost of raw materials is also going up across all commodities, meaning that manufacturers need to be acutely dialed into this sphere of operations, too. Managing these headwinds is fundamental to being able to maintain existing products, and more so when working to develop new products.

Again, directly negotiating with component manufacturers with a view to expanding your supply base and increasing your options for low-cost parts is crucial. Similarly, a partner like Plexus – who has in-house supply chain experts – can help teams determine what strategy is right based on the situation.

The benefits of sustainable manufacturing

Where does sustainability fit into all of this? Given the impact of supply chain challenges, manufacturers could be forgiven for thinking that sustainability concerns can wait. But in fact, thinking strategically about how to use existing materials and parts more efficiently will help you address both component shortages and ESG responsibilities.

First, prioritising longevity and serviceability at the product design stage will increase the functional lifespan of your products, in turn reducing waste and improving the overall value and quality of your offering. Second, working to remanufacture, repurpose and upgrade used parts to reintegrate them into your manufacturing processes will also reduce waste as well as circumventing component scarcity. And third, leaning into the growing trend of manufacturing products closer to the end market will ensure you minimize waste within your manufacturing cycle, limit emissions, and reduce your time to market.

Plexus has extensive experience in all three areas and is able to support you in building the capability and infrastructure necessary to integrate an effective sustaining services program, drive availability of parts, and assist in design optimisation. Furthermore, our global presence means we can match up you with the end customer’s manufacturing footprint, across EMEA and APAC.

A comprehensive approach

It is clear that heavy equipment manufacturers are today facing challenges of extraordinary complexity.

A partner like Plexus can help navigate this burden and reduce stress on teams. We can help craft and execute a comprehensive strategy, from design and development to manufacturing fulfillment, maintenance and remanufacturing support. Our familiarity with complex product designs, supply chain strategies and all aspects of the product lifecycle allows us to bring holistic thinking to industrial and heavy equipment projects.

Navigating the evolving heavy equipment trends can be a tall task for any team. But with years of experience in heavy equipment programs, Plexus has the passion, experience and agility to support manufacturing teams. We are committed to helping customers bring the best heavy equipment products to market. Get in touch with our team today so we can understand current needs and provide guidance on how we can partner together.