Impact of Electrostatic Discharge (ESD) on Factory Floor

By Gordon McAlpine, Production Manage, Dynamic EMS.

Electrostatic discharge (ESD) is the sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown. A build-up of static electricity can be caused by tribocharging or by electrostatic induction.

It has a dramatic impact on the shop floor. Sometimes these impacts can be blatantly obvious, like igniting solvents, and in other occasions, they can be less obvious, like dust build up, coating problems, and components jumping out of tape and reel. Then there can be the scenario of ‘ESD sales by fear’, where the ESD experts will make you believe that you need an ESD wrist strap to ground you whilst you use your mobile phone. It can go from one extreme to the other when discussing ESD.

How to keep on top of ESD

ESD is a concern in the Electronic Manufacturing Service (EMS) environment, but in manufacturing it’s more to do with the environment than ESD alone.

Static electricity is an issue in a variety of environments. One of the earliest examples of wrist straps for example, was during the Second World War where operators mixing explosive materials were earthed.

In the manufacturing environment, the biggest risk of static charge comes from people. To take precautionary steps, machinery should be wired correctly and earthed, as should benches. You should consider every person to be a mobile static generator. Their movement, no matter how slight, will generate static electricity, with walking around the shop floor generating the highest degree.

Of course, there are mitigating factors that aid or diminish static charges through dissipation:

- 1 megohm current limiting resistor straps

- Static mats and benches earthed through a resistor

- Humidity. Levels of 50%RH and above have been found to reduce the risk of static build up in people

And the opposite is true when static levels are lower, with increased dust levels causing blocked placement nozzles, drying out of solvents, lubricants and oils. In electronics manufacturing we can see 0402 chip resistors start to jump out of reel pockets at 35%RH, solder paste viscosity increases due to drying out, which also increases the risk of blocked apertures in stencils, so it’s easy to see the impact of static electricity and humidity on product throughput.

Most ESD testing involves specialist equipment which gives you a pass or fail, and of course this type of testing is valuable. However, investigating or even just daily monitoring can be cumbersome, especially in a high-paced, high mix/low volume modern facility. We needed to find a quick and simple way of monitoring our ESD protection systems.

If you accept that the largest contributors to ESD are humidity and people, such as a shop floor machine operator, then measuring and recording humidity can be easy. What you now need to establish is at what level the humidity is within our environment and do we have an issue?

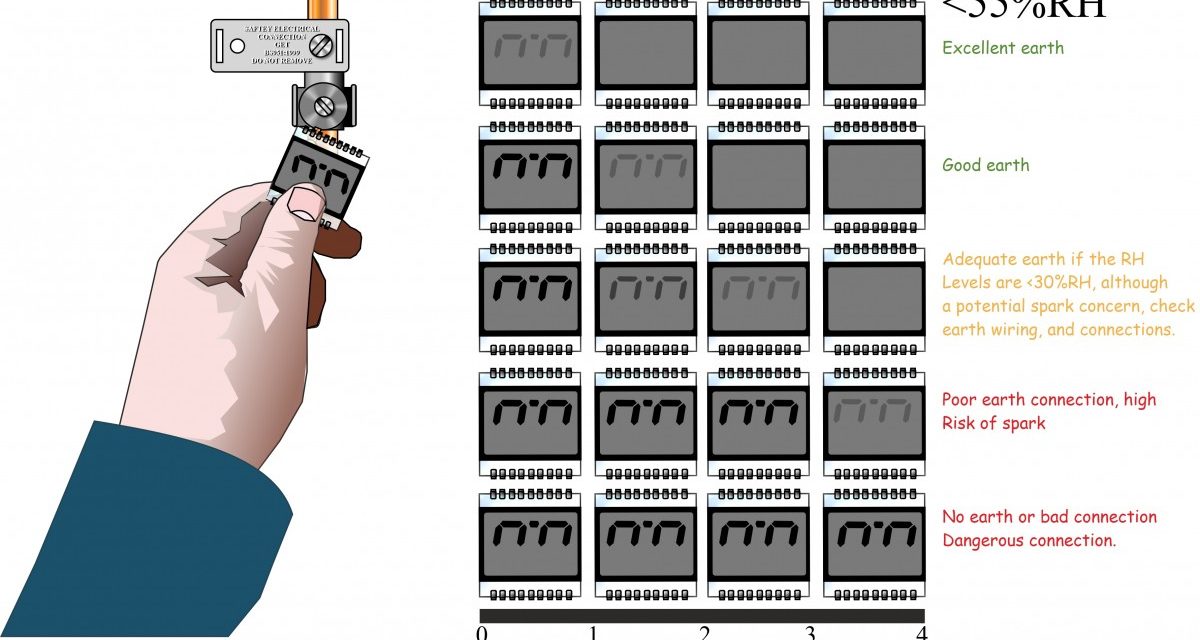

How: We used an LCD display. This high impedance component works on very low energy like static.

What to measure:

- Earthing of machines and benches

- Board storage areas

- Wrist straps

- Anywhere a person touches or carries a PCBA

The human body model charging force to the LCD display

When a person moves, they build up static charges. The charge decay/drain is dependent on whether there is a connection (drain source) to earth, in most cases this drain source is either through wrist straps (when sitting etc.) or heel straps (when walking).

High humidity drains the charge, at 50%RH, so for example it is difficult to generate static, as these types of current drain paths have high resistance which limits the current flow, and slows the decay time, safely discharging the potential damaging charges to earth. These connections are classified as soft earths.

Soft earth connections decay the charge in a slow controlled manner. Hard earths on the other hand, (where the connection is a direct low resistance path to earth), discharge the charges instantly, which causes the thermal damage (melts the aluminium traces of the silicone devices) to semiconductors, as the unrestricted instantaneous current is very high.

Static charge powers the LCD display resulting in random display characters to show.

At low humidity <45%RH, the display can show whether there is static charge build up, or if there are weaknesses in the electrical earthing within the facility. If the charges cannot be drained to earth, the charge will remain where it will continue to build up and the display bars will show in the display.

At <45%RH, this chart shows the typical display bar segments visibility dependant on the integrity of the electrical earthing.

At 50%RH, it is very difficult to generate static charges, although bad earthing will still show up in the display, even at high humidity.

That’s how we tackle ESD at Dynamic EMS, but should this insight have stemmed any questions, please don’t hesitate to reach out to talk to resident expert, Gordon McAlpine, our Production Manager.